Semiconductor supply news trends: what you need to know

Semiconductor supply chains are evolving rapidly due to global events, emphasizing sustainability, automation, and collaboration among key players to enhance resilience and efficiency in meeting increasing demand.

Semiconductor supply news trends are shaping the future of numerous industries. With ongoing developments, it’s crucial to stay informed about the latest shifts and what they mean for businesses and consumers alike.

Current state of semiconductor supply chains

The current state of semiconductor supply chains plays a significant role in technology today. As demand for electronic devices increases, understanding these chains becomes vital. Various factors influence their stability and efficiency, leading to an evolving landscape.

Challenges Facing Semiconductor Supply Chains

Several elements affect the smooth operation of semiconductor supply chains. For instance, production delays can result from natural disasters or equipment failures. Additionally, the global pandemic has highlighted vulnerabilities, disrupting manufacturing and logistics.

Key Factors Impacting Supply Chains

- Global demand: The surge in demand for technology-rich products is stressing supply chains.

- Manufacturing capacity: Limited fabrication plants struggle to keep up with the rising orders.

- Geopolitical tensions: Trade restrictions can disrupt supply chain flows significantly.

These challenges create a ripple effect throughout industries relying on semiconductors. Companies must adapt quickly to manage risks. Collaboration among industry players is essential for ensuring a more resilient supply chain.

Understanding the current state of semiconductor supply chains requires awareness of the global context. International trade dynamics, technological advancements, and consumer trends all contribute to shaping these networks. As manufacturers work diligently to increase output, innovations in production methods are becoming more critical than ever.

Each step in the supply chain, from raw material sourcing to delivery, is interconnected. This interdependence implies that disruptions in one area can lead to significant impacts elsewhere. Therefore, many companies are investing in diversifying their supply sources to mitigate potential risks.

Key players in the semiconductor market

Understanding the key players in the semiconductor market is essential for grasping how this vital industry functions. Several major companies dominate this space, shaping the landscape with their innovations and production capabilities.

Leading Companies in Semiconductors

A few giants have emerged as leaders, playing critical roles in the semiconductor supply chain. Companies like Intel, Samsung, and TSMC are known for their cutting-edge technologies and substantial market shares. Each company has its unique strengths that contribute to their success.

Key Collaborations

- Partnerships: Collaborations between tech companies and universities enhance research and development.

- Joint ventures: Resources pooled through joint ventures enable faster innovation and risk-sharing.

- Supply chain alliances: Strong alliances support and streamline the manufacturing processes.

The interplay among these companies influences both market dynamics and advancements in technology. Continuous innovation is vital for maintaining competitive advantages. As the demand for more powerful and efficient chips grows, these key players are pushed to innovate rapidly.

Moreover, emerging companies are also gaining traction, providing niche solutions and specialized products. Startups focusing on unique applications are carving out their share of the market by addressing specific needs in sectors like automotive and healthcare. The competition fosters a vibrant ecosystem where established players strive to adapt and expand.

Impact of global events on semiconductor trends

The impact of global events on semiconductor trends is profound and far-reaching. Each event can ripple through the industry, affecting everything from production capacities to pricing models.

Global Disruptions and Their Effects

World events such as pandemics or geopolitical tensions have significant implications. For example, the COVID-19 pandemic caused widespread disruptions in various sectors, including manufacturing and logistics. Facilities worldwide faced shutdowns, leading to a backlog in semiconductor production. As a result, companies experienced supply chain challenges, which increased lead times and costs significantly.

Key Global Factors Influencing Trends

- Trade Policies: Tariffs and restrictions can limit access to essential components.

- Natural Disasters: Events like earthquakes or floods can halt production.

- Technological Innovations: Rapid advancements can shift demand in unexpected ways.

Additionally, market responses to these events often include increased investment in local manufacturing to mitigate risks. Companies are exploring ways to build resilience against these disruptions by diversifying suppliers or increasing inventories. This shift indicates a strategic move towards greater stability in supply chains.

The intertwining of global events and semiconductor trends underscores the necessity for companies to remain agile. Staying informed about global developments can help organizations predict changes and adapt strategies accordingly. As pressures mount, market players must innovate and find creative solutions to navigate these challenges effectively.

Future outlook for semiconductor supply chains

The future outlook for semiconductor supply chains is a topic of great interest and importance. As technology evolves, so do the demands on supply chains, shaping their structure and strategies.

Emerging Trends in Supply Chain Dynamics

One significant trend is the push towards sustainability. Companies are increasingly focused on creating eco-friendly processes. This shift includes reducing waste during production and sourcing materials responsibly. As consumers become more environmentally conscious, businesses must adapt to these expectations.

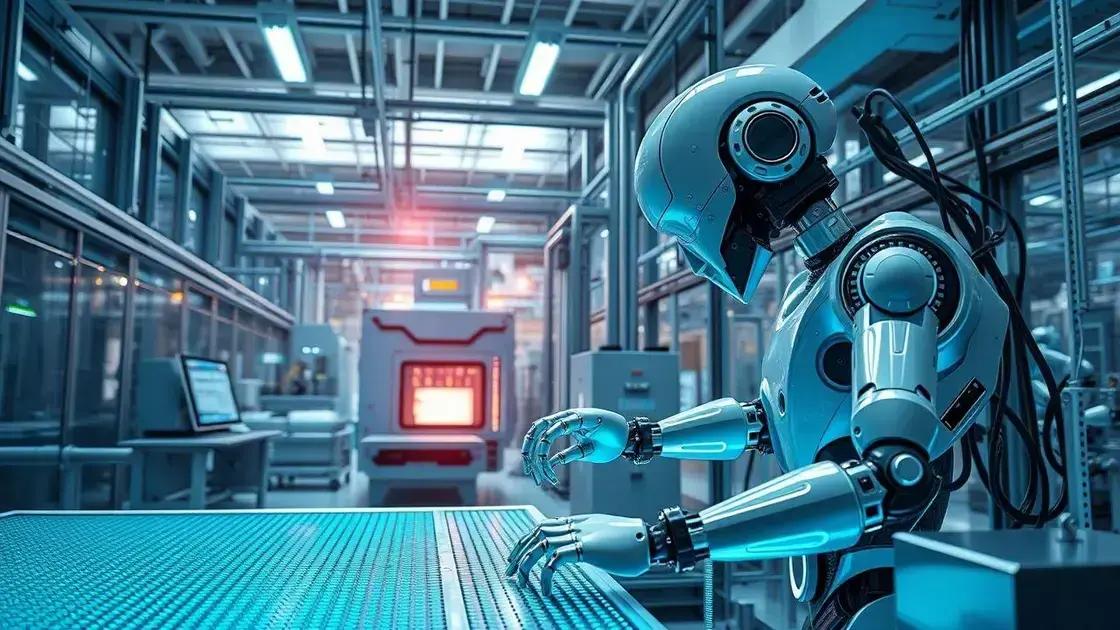

Technological Innovations Driving Change

- Automation: Automation in manufacturing processes enhances efficiency and precision.

- Artificial Intelligence: AI helps optimize supply chain operations and demand forecasting.

- Blockchain: This technology improves transparency and traceability in supply chains.

These innovations not only improve operational efficiency but also create a more resilient supply chain. As incidents like the pandemic have shown, agility and adaptability are key. Companies that invest in advanced technologies are better prepared to respond to disruptions.

Another essential factor is the reshoring of semiconductor production. Many countries are seeking to decrease reliance on foreign manufacturers, especially in critical sectors. This move can lead to a more stable supply chain, fostering local economies while ensuring consistent access to essential components.

As the semiconductor market grows, collaboration among companies will play a crucial part in shaping its future. Sharing resources and knowledge can lead to breakthroughs that benefit the entire industry. This collective effort will help tackle global challenges and pave the way for future advancements.

The semiconductor industry is at a crossroads, facing both challenges and opportunities. As we look towards the future, it is crucial for companies to innovate and adapt to changing trends. Embracing sustainability, automation, and collaborations will help create resilient supply chains. By understanding the impact of global events and being proactive, businesses can position themselves for success in this dynamic market.

FAQ – Frequently Asked Questions about Semiconductor Supply Chains

What are the main challenges facing semiconductor supply chains?

Main challenges include production delays, supply disruptions due to global events, and increasing demand outpacing manufacturing capacities.

How is sustainability impacting the semiconductor industry?

Sustainability encourages companies to adopt eco-friendly practices, reducing waste and focusing on responsible sourcing.

What role does automation play in semiconductor manufacturing?

Automation increases efficiency and precision, helping manufacturers keep up with rising demand and reduce operational costs.

Why is collaboration important in the semiconductor market?

Collaboration among companies leads to resource sharing, innovation, and improved capabilities, enhancing overall supply chain resilience.